HIGH FREQUENCY WELDING

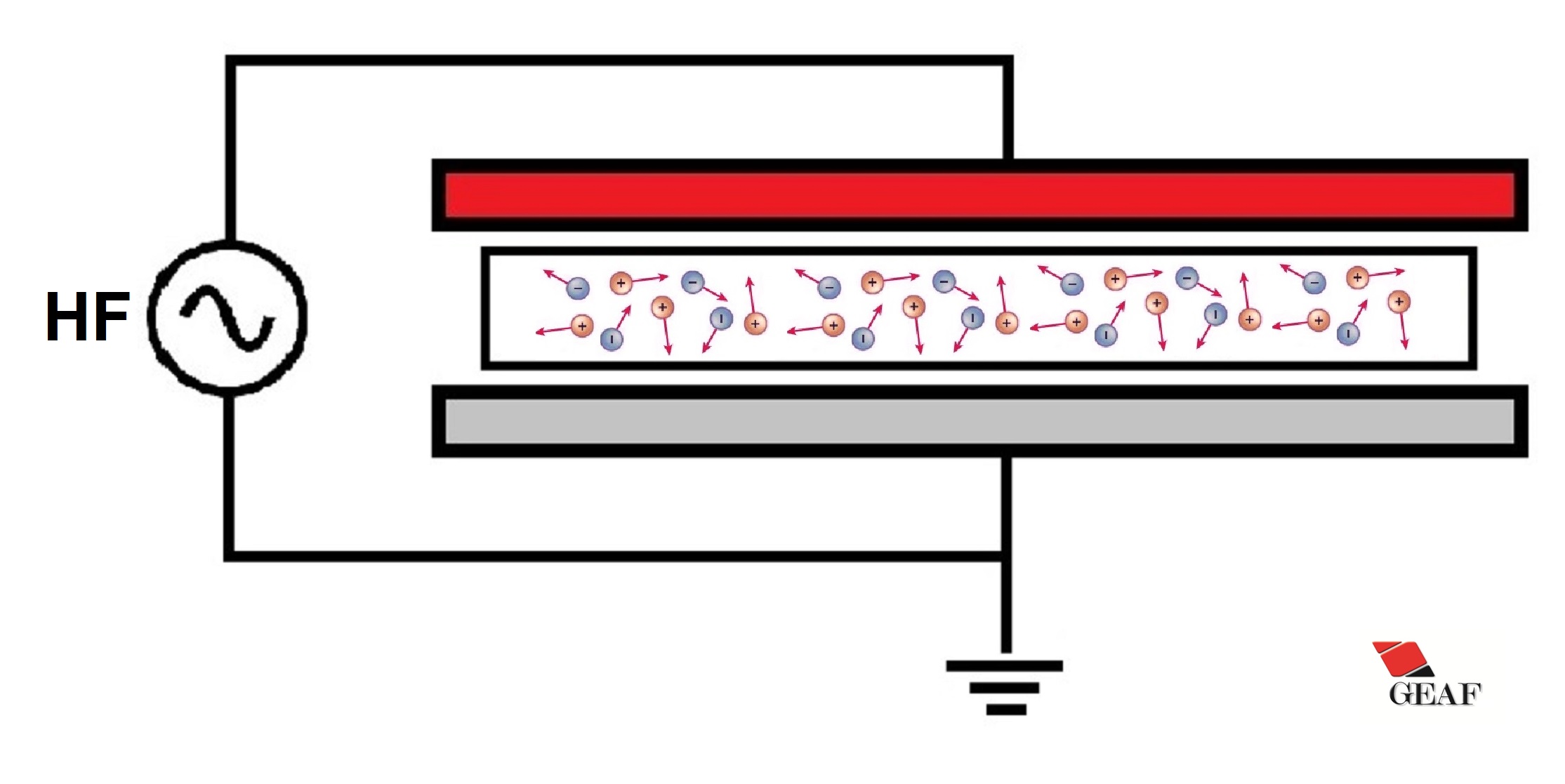

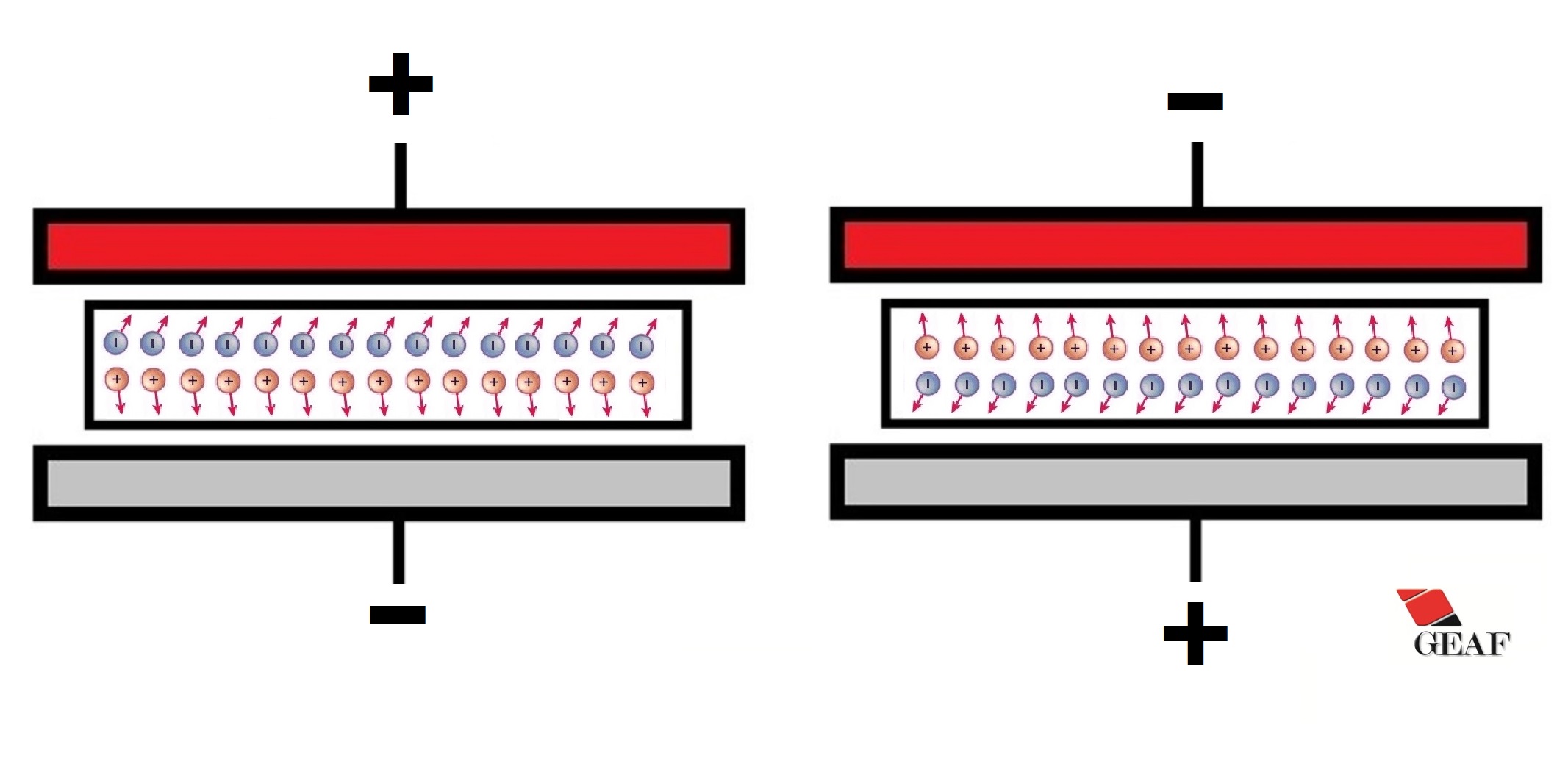

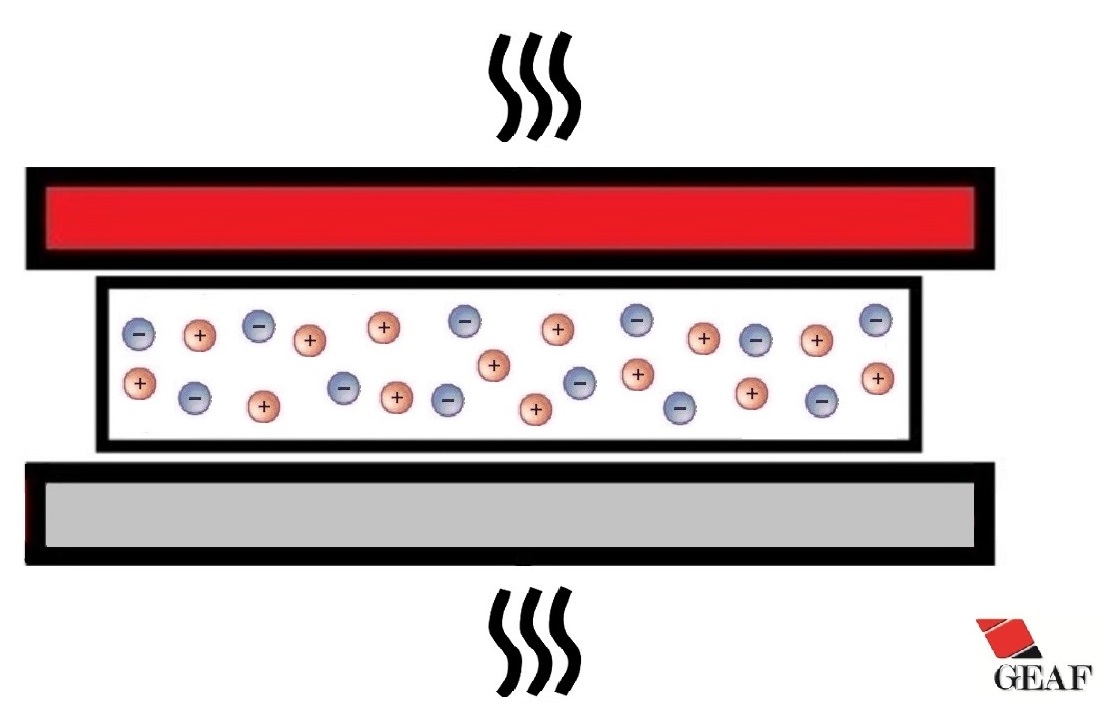

High frequency welding (also called radio frequency welding) is a clean technology, that through the simultaneous application of a pressure force, and an electromagnetic field with a frequency of 27.12 MHz, acts on the molecules of plastic materials (for example 2 PVC films). This process makes the material weldable at relatively modest temperatures (for example 30°C), and it guarantees a safe and durable connection of different products remaining welded over long periods of time.

Unlike other welding technologies, high frequency welding, if compatible with the materials, offers important advantages: strongly resistant welds, optimization of energy consumption, it does not generate fumes, it does not require the use of additives – relevant aspects both in terms of operator safety and environmental protection.

Depending on the result of the welding tests, GEAF is able to produce high frequency welding machines 27.12 MHz, or 13.56 MHz, or 40.68 MHz, which are the frequencies allowed by the laws in force.

Examples of materials reactive to the application of high frequency welding include: PVC, EVA, PU, TPU, PET-G, PET-GAG, PET-A, PET-R (not in all cases), ABS.

THERMO-CONTACT WELDING

Thermo-contact welding is a traditional welding technology, which is used to weld

plastic materials non-reactive to high frequency applications.

Through the simultaneous application of pressure and temperature, (depending on the characteristics of the type of material to weld), the material is melted to obtain the weld.

Some of the materials that can be thermo-contact welded include: PP, PE, PVC-FREE, NON-PVC.

TURNKEY PLANTS

By following customer specifications, collaborating with skilled suppliers and using experience gained over many years, GEAF is able to design and offer complete automatic systems for the production of high technology products.

Since 80’s GEAF has been developing, both internally and through partnerships with leading companies, new applications based on specific requests. GEAF is able to integrate various technologies, like for example:

- Thermal pulses welding

- Ultrasonic welding

- Laser cutting

- Hot foil printing, thermal transfer, flexographic, laser, etc.

- Vibration selection systems

- Glue dosing system

- Tubes closing systems

- Labelling systems

- Corona or plasma surface treatments

- Robot handling

- Control systems with cameras

- Automatic leak-test stations

QUALIFIED LABORATORY

GEAF is a qualified laboratory– Art. 14 Law 46 (G.U. n° 283 dated 2/12/88) for research, development and set up of new prototype projects.