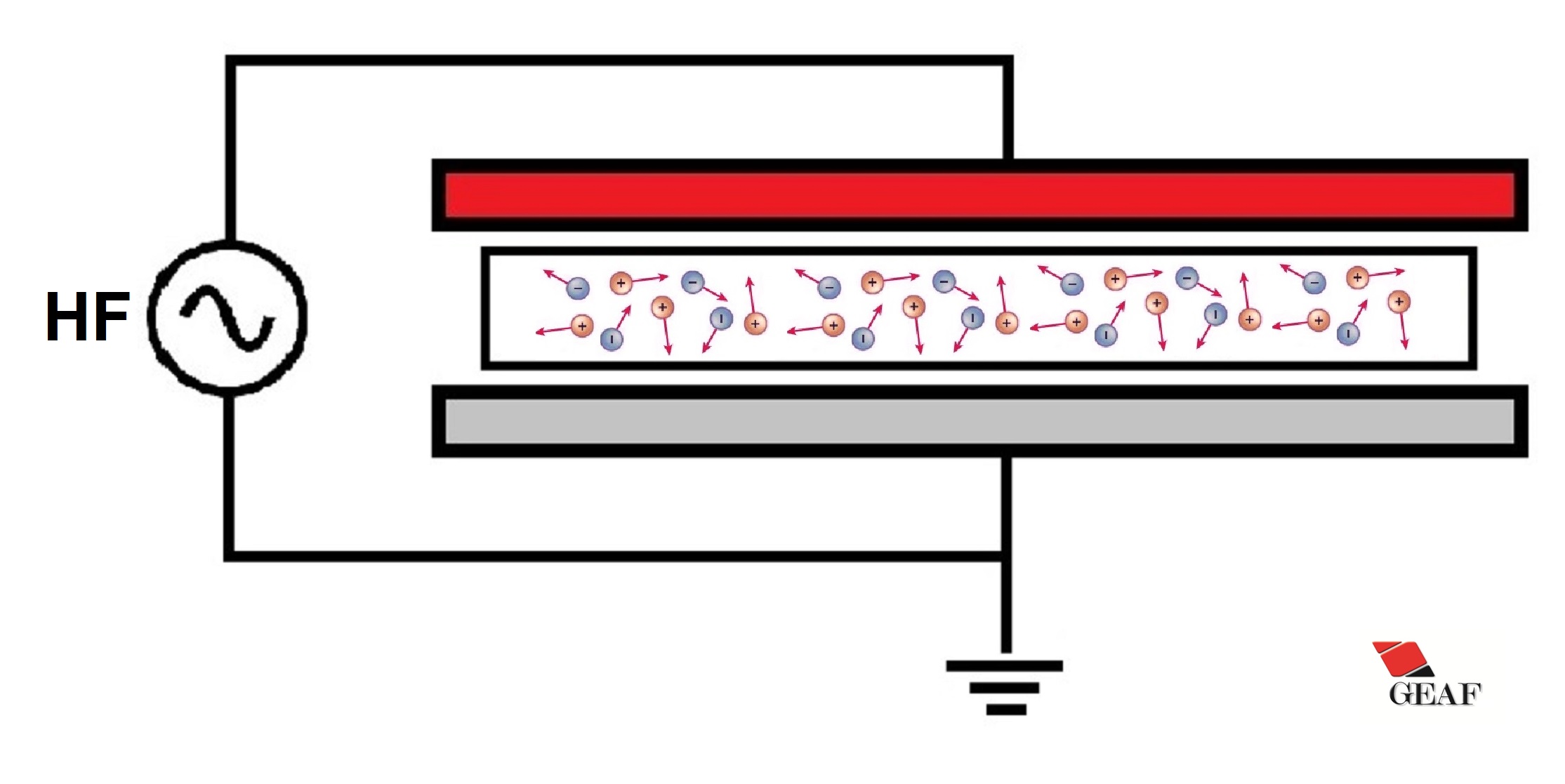

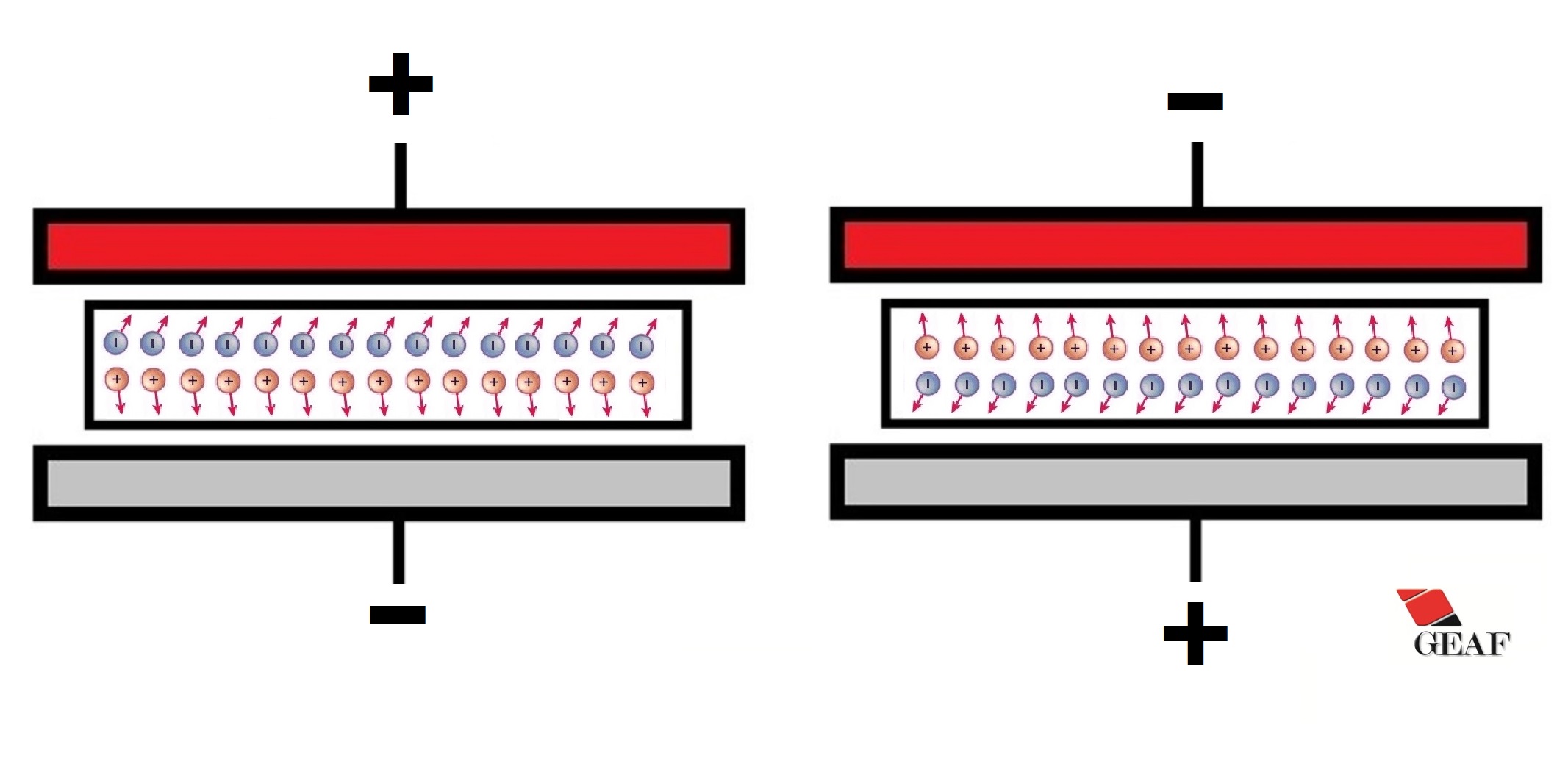

High frequency welding (also called radio frequency welding) is a clean technology, that through the simultaneous application of a pressure force, and an electromagnetic field with a frequency of 27.12 MHz, acts on the molecules of plastic materials (for example 2 PVC films). This process makes the material weldable at relatively modest temperatures (for example 30°C), and it guarantees a safe and durable connection of different products remaining welded over long periods of time.

Unlike other welding technologies, high frequency welding, if compatible with the materials, offers important advantages: strongly resistant welds, optimization of energy consumption, it does not generate fumes, it does not require the use of additives – relevant aspects both in terms of operator safety and environmental protection.

Depending on the result of the welding tests, GEAF is able to produce high frequency welding machines 27.12 MHz, or 13.56 MHz, or 40.68 MHz, which are the frequencies allowed by the laws in force.

Examples of materials reactive to the application of high frequency welding include: PVC, EVA, PU, TPU, PET-G, PET-GAG, PET-A, PET-R (not in all cases), ABS.